In the 1950s cellophane was the only clear film material available as flexible packaging material. In the 1960s, flexible packages started to evolve, with new processes and material innovations introduced at a daily basis. While many bags and pouches were made of coated papers, polypropylene and polyethylene came along, followed by co-extrusions, coatings and laminations, which were hailed as two of the biggest breakthroughs in flexible packaging.

According to the FPA (Flexible Packaging Association), plastic consumption by flexible packagers grew at double-digit rates throughout the 1960s and 1970s as preformed pouches got jump-started.

Four or five decades later, in 2008 the European flexible packaging market totalled USD 15.22 billion in sales, thanks mainly to the green credentials flexible packaging is supposed to have in comparison with other packaging formats. To underscore this statement, the FPE (Flexible Packaging Europe) is emphasizing the “product-to-packaging ratio”, along with full life cycle analyses. For example, in contrast with a metal can, plastic jar and flexible “brick-pack” (each holding 11.5 oz/325 gr of coffee), the flexible packaging wins hands-down. Its 29:1 ratio versus the can’s 5:1 and the jar’s 3:1 clearly shows “flexible packaging as the most resource-efficient.

Although recent studies indicate the end of a strong grow of converted flexible packaging in the USA and Europe, the flexible packaging will see, in my opinion, many more new applications as no continental market on the planet is “eco-hotter” than Europe in terms of sustainability and recyclability.

The flexible packaging market includes all kinds of pouches, but the popular stand-up pouch was and still is the most impressive driver in the flexible packaging market, particularly with the breakthrough of the various material compositions, the re-closable zipper and other fitments that enhance consumer convenience, and have led stand-up pouches move dramatically into new applications.

The flexible packaging market includes all kinds of pouches, but the popular stand-up pouch was and still is the most impressive driver in the flexible packaging market, particularly with the breakthrough of the various material compositions, the re-closable zipper and other fitments that enhance consumer convenience, and have led stand-up pouches move dramatically into new applications.

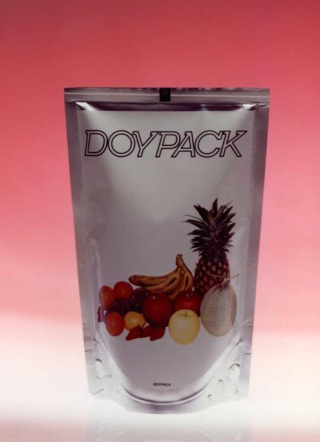

The stand-up pouch found it’s origin in 1968, when Louis Doyen, CEO of the French packaging machinery manufacturer Thimonnier, obtained US Patent 3,380,646 for a stand-up pouch design. That pouch design, including many variants, is still in use today. It is, in fact, the dominant style. The basic Doyen design consists of two flat sheets seamed together along their sides, with a “W” fold running along the bottom and sealed to the tube wall with an upside-down U-shaped area. When the pouch is filled, the “W” (also called gusset) opens and provides a circular base on which the pouch can stand. The original Doyen design showed the top being sealed straight across, but subsequent modifications include fitments of all sorts.

Albeit a revolutionary design with great market potential the DoyPack stand-up pouch didn’t lead to a revolution in the packaging world, mainly because the pack was much more expensive than the standard pillow pouches or even the bottles, jars and cartons it should replace. Sustainability and environment were no core issues in the 1970s.

Albeit a revolutionary design with great market potential the DoyPack stand-up pouch didn’t lead to a revolution in the packaging world, mainly because the pack was much more expensive than the standard pillow pouches or even the bottles, jars and cartons it should replace. Sustainability and environment were no core issues in the 1970s.

In the USA, Capri Sun was with its juice drinks at the forefront to introduce the stand-up pouch in the 1980s. But it wasn’t until the turn of the century, when the patent of the Doyen Brothers expired that stand-up pouches as we know them today truly established a strong market presence and made a major market impact by replacing other types of containers.

Of course the stand-up pouch, DoyPack as it was originally named, Doyne-style stand-up pouch, a bottom-gusset stand-up pouch or flexible can or flexible bottle as enthusiasts like to call it, evolved over the years, as the original DoyPack had various shortcomings, which had to be solved to meet the explosion of innovations in materials, printing techniques and manufacturing of fitments, like spouts, built-in straws, zippers etc.

Of course the stand-up pouch, DoyPack as it was originally named, Doyne-style stand-up pouch, a bottom-gusset stand-up pouch or flexible can or flexible bottle as enthusiasts like to call it, evolved over the years, as the original DoyPack had various shortcomings, which had to be solved to meet the explosion of innovations in materials, printing techniques and manufacturing of fitments, like spouts, built-in straws, zippers etc.

Speaking in general terms there are two shortcomings in the Doyen style pouches.x One is that, because the DoyPack body tapers from the circular bottom to the flat lined top and is fabricated from two flat sheets, the pouch when partly full, or better still, half empty tends to cause the top of the pouch to fold over, rather than stand erect, due to the weight of the fitment.

Speaking in general terms there are two shortcomings in the Doyen style pouches.x One is that, because the DoyPack body tapers from the circular bottom to the flat lined top and is fabricated from two flat sheets, the pouch when partly full, or better still, half empty tends to cause the top of the pouch to fold over, rather than stand erect, due to the weight of the fitment.

The second shortcoming is the difficulty in adding a fitment, other then a zipper, to a DoyPack pouch and to many other pouch designs as well. Due to fitment sealing methods and the construction of the stand-up pouch, the fitment must be of the “canoe” style to create a joint that can be reliably sealed. The canoe type of fitment is an attempt to minimize the change in direction of pouch material as it comes into contact with the fitment, and in doing so, improve the integrity of the joint where the two sides of the pouch come together at the fitment. However, even the use of a canoe shaped fitment does not completely solve the difficulties in sealing a fitment into a stand-up pouch, what many a designer brought to the decision to locate the fitment in the front of the packaging. Some recent developments show the introduction of a gusset at the top of the pouch to create a flat surface for the spout fitment.

In the next post we shall take a look at some stand-up pouches which feature in one way or another a speciality. There are innumerable ways to design original stand-up pouches using the ultimate in technology to accentuate the brand’s presence on the shelves. Keep in mind that more than two thirds of purchasing decisions are made in the aisle. The competition is decided then and there by what the consumer favours, and it is on the shelves that the brand must make the impact. The only problem is, as it is often in the packaging world, the application of revolutionary technologies and/or material compositions, isn’t always recognised or even recognisable by the consumer.

In the next post we shall take a look at some stand-up pouches which feature in one way or another a speciality. There are innumerable ways to design original stand-up pouches using the ultimate in technology to accentuate the brand’s presence on the shelves. Keep in mind that more than two thirds of purchasing decisions are made in the aisle. The competition is decided then and there by what the consumer favours, and it is on the shelves that the brand must make the impact. The only problem is, as it is often in the packaging world, the application of revolutionary technologies and/or material compositions, isn’t always recognised or even recognisable by the consumer.

90930

Stand up pouches are much cheaper and more economical than tins of the past. Pouches also make better use of space for the given product, provided the manufacturer’s design is well matched.

Pingback: Excellence in Packaging » Blog Archive » 4-Fresh or Quattro – Original or Copycat·

Pingback: The Evolution of the Stand-Up Pouch « Best In Packaging - packaging-radar.com·

Although the advantages of stand up pouches are indisputable, they do require additional support to efficiently distribute and handle them in productivity driven retail supply chains. Shopper impact heavily depends on retail operations for proper display.

Especially in Europe, retailers increasingly require units that are easy to handle, stack and present. Stand up pouches fall in the category of “problem items” that are lobour intensive and require continuous attention and support. The answer is intrated design and management of primary and secondary packaging in order to be truly competitive. A balanced approach to overall effectiveness will make the packaging not only cost- but also eco-efficient!

Very Nice Information

there are also a website providing good information, kindly visit http://www.standypouches.com/

Pingback: Everything Related to Packaging || the Evolution of the Stand-Up Pouch « Best in Packaging·

Pingback: The Evolution of the Stand-Up Pouch (Part 2) « Best In Packaging·

Hello,

i’m looking for stand up pouches in 200g, 300g 500 and 1kg for food products and spices.

i would like some type of printing on this also.

Please could you snd me a price for bags and cost for printing and also your min quanity orders..

Best regards

Anjum

Interesting article.

Your readers may also be interested in our latest market study “The European Stand Up Pouch Market 2009” which provides a detailed assessment of market size and trends in demand for both retortable and non-retortable pouches, identifying and describing the rapidly growing number of food, beverage and non-food end-use applications that now use the stand-up pouch format.

The report covers both pre-made pouches and material supplied on the reel to packers for form fill seal, with forecasts through 2014. The report includes markets in Western, Central and Eastern Europe, including Russia.

For further details contact Joanna at j.smith@pcifilms.com.