Already for years you can’t sit quietly around a table during a birthday party with friends, discussing the oh-so simple solutions for the world problems and then telling them you’re a packaging specialist. Within seconds the whole crowd is rolling over you, blaming you for all the shortcomings in the world of packaging and, of course, particularly, with the skin packs, blister packaging and plastic clamshells. Blaming you, that you, personally, make life of the consumer a hell.

All world problems and their simple solutions are forgotten and the birthday party turns around in a court case with the obvious verdict. All companies presenting their products in blisters or clamshells as well as their packaging designers are idiots and packaging technologists aren’t worth their salt.

And I must say they have a point.

I don’t want to discuss the irritating packaging of a Barbie or some other idiotic doll, which is once a year bought as a present and for which all the tools in the household have to be used to finally free the oh-so desired toy from its shackles. No, that situation is of no importance and by the way gives some extra flavour to the birthday party discussions.

No, the irritation with blister and clamshell packaging is in the day-to-day environment. The product the consumer uses and consequently buys almost daily and let him time-after-time fight to open the packaging.

According to pro-consumer group Which? almost 90% of people resort to scissors, more than 60% grab a knife, 4% deploy a razor blade and 2% take to it with a hammer, as far as trying to open moulded plastic packaging is concerned.

Consequently Which? states that consumer purchasing behaviour is influenced by the packaging they’re presented with. Some 20% of people might not buy certain foods if the packaging looks like it might present a challenge, while 75% are adamant that, these days, packaging is unnecessarily hard to open.

Joanna Pearl, a researcher at Which? said: “If you bought a car you’d be furious if it proved difficult to open the door, but the struggle to get into everyday packaged goods is seen as something we must tolerate”.

Moulded plastic ‘clamshell’ packaging as well as blisters are the leading causes of frustration, followed by shrink wrapping and peel-off coverings. And as heat-sealed plastic clamshells are the most hated packaging, we do, consequently, face the well-known advice that they should be avoided by manufacturers at all costs.

And, of course, what do you think the answer of the industry is? Dick Searle, chief executive of the Packaging Federation, the ‘over-arching’ trade association for the UK Packaging Manufacturing Industry, admitted that some clamshell packs were unnecessarily difficult to get into, but said: “If you are opening a food pack, in a kitchen, you are likely to have a pair of scissors to hand”.

As short-sighted as ever!

Fortunately there are some companies, which have a more nuanced approach to the problem. Let’s have a look at the latest progressive developments in blister packaging and clamshells.

After breaking the perforations in the blister pack using light finger pressure the consumer can bend the top of the package. More about this Gillette packaging in the next article.

Procter & Gamble through Gillette has been very active to create new sophisticated designs for clamshells for its personal care products. That supplies a very interesting story, but I want to start with some less famous, simple, but creative designs. In the next article I will describe the designs of the clamshells by Procter & Gamble.

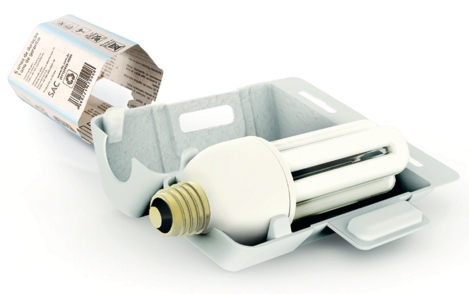

LED light bulb packaging

Akihiko Kotani and Mitsutoshi Ohta designers in Tokyo, Japan, created for Panasonic Corporation in Osaka, Japan, a LED light bulb packaging with a paper craft-like structure.

The packaging can just be folded without the need for heat moulding. The packaging simply divides into transparent PET plastic and cardboard, which makes for easy disposal of the separated components. And because there is no printing on the case, there are no impurities such as ink to deal with, which makes recycling easier.

The one-touch pinch-and-pull opening allows the consumer to extract the products easily. The packaging is shaped to fit well in the hand, and checking what is inside through the packaging is easy. Particular consideration has been given to prevent incorrect purchases by enabling customers to touch and check the metal caps.

Lamps are a hot item in terms of clamshells and blister packaging. Besides Panasonic, Brazilian designers also created a workable alternative.

FLC Sustainable fluorescent lamp packaging

Despite its characteristics such as greater energy efficiency and life expectancy in comparison to incandescent lamps, fluorescent lamps contain toxic residues which may contaminate the environment in case of inappropriate discard or accidents regarding its handling and transportation.

For a college project executed for FLC, a Brazilian fluorescent lamp company, Guilherme Parolin, and Fabrício Vaz, both students at the UFRGS – Universidade Federal do Rio Grande do Sul in Porto Alegre/Brazil, designed a packaging for a fluorescent lamp.

The FLC sustainable packaging, beyond a mere packaging, proposes a new kind of relationship between the consumer and the fluorescent lamp by facilitating the return of the replaced, old or damaged bulb to its manufacturer and its due recycling.

The package, composed mainly from moulded paper pulp, offers an efficient protection of the new lamp from the point of sale to its place of use, and acts, in its second life, as a protective case for the inoperative lamp, which can therefore be discarded safely in domestic waste or forwarded to a proper waste collection point.

Moulded ribs and latches inside the packaging ensure a correct positioning and fixing of the lamp against possible impacts. The hexagonal shape offers greater stability and better use of space at the point of sale. The sleeve, made from recycled paper provides the relevant information to the consumer in a hierarchical way.

Although the designers claim that its major innovation is the use of moulded paper pulp, in the same way as for egg packaging, to ensure the protection and safety of the lamp, the result is a “blind” packaging. The consumer can’t see the product.

To create a positive visual impact it would be interesting to execute this packaging in a thermoformable recyclable plastic film, which would allow for a consumer-friendly clamshell by its longitudinal opening and the use of the reliefs for a better ergonomic performance.

Curved blister pack

The Curved Packaging Solutions from Sonoco Alloyd creates a curved blister pack designed to differentiate products on a crowded retail shelf.

The product receives its curve from three sources:

(1) The thermoformed front blister is made with a curve,

(2) The nesting trays on the company’s Aergo 8 heat sealer have smooth curves matching the front blister,

(3) The heat-seal platen that comes down to seal the layers is also curved to the degree of the nesting tray/blister.

With this concept, packages can be made with a single or serpentine curve and with a concave or convex curve. Suitable for trapped-blister packs and products sold at club stores, the Curved Packaging Solutions package made its commercial debut at EastPack 2014.

Clamshell for fruit with ripeness indicator

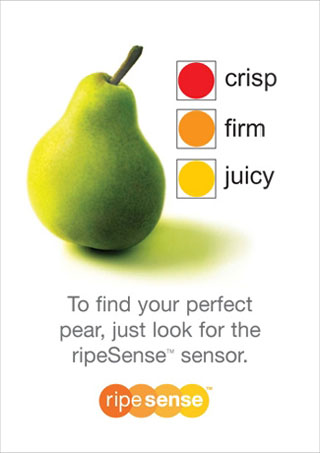

Declining global consumption of fresh fruit and vegetables has been concerning health professionals and produce trade leaders for some time. Convenience and taste have been identified as key drivers to encourage increased consumption. The RipeSense label can be expected to change the way shoppers buy fruit by showing the exact level of ripeness without handling or guesswork.

The clamshell pack, moulded to the shape of the pears, was developed to trap the aroma necessary for the ripeSense label to function, while the key reason for developing ripeSense for pears is the difficulty shoppers have determining fruit ripeness.

Pears, unlike apples, need to soften before they achieve their maximum flavour and shoppers often squeeze and damage the fruit as they make their selection. The clamshell protects the pears from crushing and bruising, permitting retailers to sell tender juicy ripe fruit without wastage.

The ripeSense sensor label is world-first technology that enables shoppers to choose fruit that best appeals to their taste. It works by detecting aroma compounds given off the fruit as it ripens, changing the label through a range of colours.

Shoppers can choose to either buy pears that are ready to eat immediately or they can purchase firmer fruit that will be ready for eating in a few days. Further research is proposed to develop sensor labels for summer fruit, kiwifruit, avocado and melons.

The new label technology is the result of five years development by HortResearch scientists, funded largely by the New Zealand Foundation for Research, Science and Technology.

The new label technology is the result of five years development by HortResearch scientists, funded largely by the New Zealand Foundation for Research, Science and Technology.

It belongs in the section of intelligent packaging that changes colour to indicate the ripeness of fruit. Developed in New Zealand, ripeSense packaging technology is expected to bring significant efficiencies to the fresh fruit industry, reducing wastage and forever eradicating the old selling process of selling loose, usually unripe, fruit into bins, where it is bruised, squeezed and prodded to determine its ripeness.

For the next article I reserved a story about the clamshell redesign of Hypertherm and the developments in clamshell design for the Easy-Open Venus and Olay Razor Packaging as well as the Venus Snap blister for the Venus line of women razors, both product lines from Gillette.

Anton,

Great newsletter. Loved it! 🙂

Abraço,

José Pedro Freitas Pinto

Diretor de Marketing

Farmacêutico

E-mail jpinto@grupo-holon.pt

TM +351 93 836 4334 T +351 219 666 101 | F +351219 666 102

Pingback: Don’t Let Your Packaging Cause “Wrap Rage” | CTI Packaging & Fullfillment - Smart Packaging·