Although I gave this article a different title, it is the continuation of my previous one, “What’s New In Child-Resistant Packaging”, regarding child-resistant packaging other than the well-known caps and closures for bottles and jars.

In this one I will describe three solutions for aerosol and spray can packaging. I have only seen the patents for these designs and never saw the solution in a commercial environment, which doesn’t say that they aren’t commercialised or worth a closer look and even a serious consideration in case a child-resistant device is required for a product packaged in an aerosol or spray can.

Aerosol or Spray Can

An aerosol or spray can is a dispenser that holds a substance under pressure and that can release it as a fine spray (usually by means of a propellant gas). This is obtained with a can that contains a liquid under pressure. When the spray valve is opened, the liquid is forced out of a small hole and emerges as an aerosol or mist. As gas expands to drive out the payload, only some propellant evaporates inside the can to maintain an even pressure. Outside the can, the droplets of propellant evaporate rapidly, leaving the payload suspended as very fine particles or droplets.

The last few years have seen a range of new developments in aerosol technology, which you can find in my article “Developments In Aerosol Technology”.

An atomizer or spray pump is a similar device that is pressurised by a hand-operated pump rather than by stored gas. About this system, which is the forerunner of the airless system in aerosol technology, you also can read more in the article cited above.

In the pharmaceutical and medical sector there aren’t that many applications of aerosols, but in the household sector you find numerous products with a hazardous content from detergents to paint and most of them unprotected to use. The most advanced brands have some sort of protection, like the Valspar Paint aerosol described here below.

In the pharmaceutical and medical sector there aren’t that many applications of aerosols, but in the household sector you find numerous products with a hazardous content from detergents to paint and most of them unprotected to use. The most advanced brands have some sort of protection, like the Valspar Paint aerosol described here below.

In 2011 Valspar Paint introduced a new spray can design. The patented spray top, an integral part of the can’s design, features a twist-and-lock device, so there is no separate top to remove or replace after use. Valspar claims that “The built-in twist-and-lock mechanism enables cleaner and safer painting and storage by preventing unintentional spraying when the cap is twisted 90 degrees”.

You see that even in its promotional text, Valspar doesn’t touch the Child-Resistant issue. Its twist-and-lock device isn’t even thought to be a child protection device. It’s just said to prevent unintentional spraying when stored.

Child-Resistant Aerosols

In general child resistant aerosol containers or spray pumps (atomizers) have a top-positioned spray actuator covered by a safety cap to inhibit dispensing of the content by children.

In the examples in this article the cap may be removed easily, but the spray actuator can’t be used. The cap has to be inverted to the bottom of the can and then used to push up the spray activator to make it ready for activation.

The devices, described here, are particularly beneficial as a retrofit child resistant container for potentially dangerous spray products to children, as the devices have, as I understand it and to make it retrofitable, an outer body, a kind of sleeve, which can be positioned around the body of an existing aerosol. In other words you can alter a normal aerosol can into a child-resistant aerosol can.

All three patents have been filed close one after the other by the same inventor, Stuart W. Dejonge.

CR Overcaps with Bottom Lift

To dispense a product using this child-resistant overcap, the consumer removes the cap, inverts it, and slides it on to the bottom of the container where it snaps into place. The inner pump or aerosol sprayer can then be pushed upward, actuating the sprayer and dispensing the product. After use, the cap is removed from the bottom of the outer container, the spray unit drops down inside, and the cap is placed back on top.

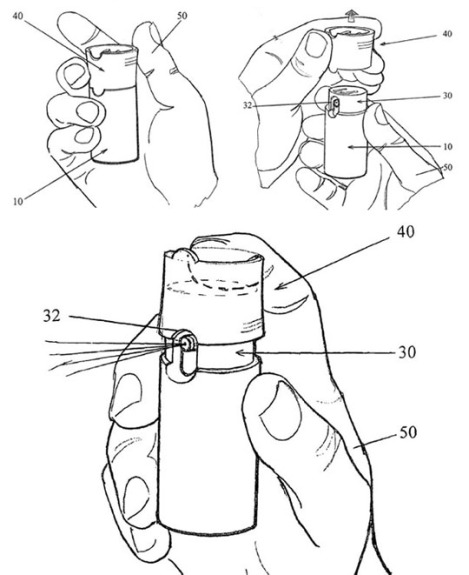

From this description you can extract that there is some from of outer container in which the original aerosol slides up and down. The patent US8544664 describes that the invention features a container main body adapted to receive a spray container with a top-positioned spray activator (this outer body or sleeve is called CR-container), and has at least one lift rod slot on its bottom; an inner cap for permanent connection to the open top of the container after a spray container is placed therein; and an outer cap with at least one downwardly projected lift rod.

The consumer removes the outer cap, inverts it and pushes up through the bottom to raise up the spray container within the outer body enough to expose the spray activator and its nozzle for spray use.

An identical bottom-lift design suitable for vertical nozzles is described in patent US8584903. In this version the consumer removes the cap, inverts it, and slides it on the bottom of the container. This pushes the spray unit up and allows the consumer to operate the sprayer in a normal way using their fingertip to actuate the unit. When finished, the consumer removes the cap from the bottom of the unit and the pump slides back down into the CR container. The cap is then returned to the top of the unit.

Similar to the previous example the invention features a CR-container (an outer body or sleeve) to receive a spray container with a vertical spray nozzle top-positioned spray actuator, and has at least one lift rod slot on its bottom; an inner cap for permanent connection to the open top of the container after a spray container is placed therein; and an outer cap with at least one downwardly projecting lift rod.

The working is identical.

In both designs the spray nozzle isn’t visible when the cap is removed, as the entire aerosol is sunk in the CR-container. The cap with its downwardly projected lift rod has to be inserted into the slot at the bottom of the CR-container and pushed-up while the fingers of the other hand secure the side of the CR-container. This pushing-up engages the spray activator.

I understand that the actions need to be executed to activate the spray nozzle are too complicated for a child to carry out. However I’m not sure the system is tested.

CR Overcap with Top Lock

To dispense a product using this child-resistant overcap, the consumer removes the cap, inverts it, and slides it back on top of the container. Downward pressure applied to the inverted cap now pushes on the spray actuator and dispenses the product. After use, the cap is removed from the top of the outer container, flipped over and placed back on top of the container.

This invention described in patent US8360281 (Child resistant container with inverting cap top key for spray activation) uses a CR-container as sleeve over an existing aerosol. In fact similar as we have seen with the above described inventions.

The CR-container has to be able to house a spray container (aerosol, atomizer) with a top-positioned spray activator and spray nozzle. Furthermore it features an inner cap adapted for permanent connection to the open top of the CR-container and having at least one key slot to permit at least one key to be inserted therein to permit a spray activator of a spray container to be activated by depression. The outer cap fits over the inner cap and has upwardly projecting key(s) for spray activation, when it is inverted and inserted into the inner cap.

So, these were the three CR-inventions for aerosols and spray cans. As I said before I have no information, whether the inventions indeed are accepted as CR and tested as such. Whatever the case the designs are very interesting and promising for a field in CR-packaging (aerosols) that’s not yet fully covered and secured.

It is an interesting development. Two-in-one packages we have seen in various formats, such as the bag-in-box, the bag-in-bottle and even the bag-in-bag. The aerosol-in-a-rigid-container with Child-Resistant facilities opens up a lot of possibilities for some clever packaging engineers.